ECPMixerGgiFvMesh3D

Contents

1 Running the case

This case is computed using the GGI interface between the impeller and the diffuser.

Follow these steps to run the case from scratch:

First make sure that you have the following installed:

- A recent revision of OpenFOAM-1.5-dev

- libOpenFOAMTurbo.so (needed for the inlet boundary condition)

- the solver transientSimpleDyMFoam compiled

- The boundary condition turboWallFixedValue compiled

- libsimpleFunctionObjects.so (or comment out the trackDictionaryContent function from ECPMixerGgiFvMesh3D/system/controlDict)

- libsampling.so (or comment out the ggiCheck function from ECPMixerGgiFvMesh3D/system/controlDict)

cd $FOAM_RUN/ercoftacCentrifugalPump/cases/transientSimpleDyMFoam/ECPMixerGgiFvMesh3D

The method of parallel computing should be used in this case, the first step is to decompose the domain using the decomposePar utility as following:

decomposePar >& log_decomposePar&

After the decomposePar finished, the parallel running in this case comes as following:

mpirun -np 32 transientSimpleDyMFoam -parallel >& log_transientSimpleDyMFoam&

After this case has been run in parallel, it can be reconstructed performed by the reconstructPar utility as the following command:

reconstructPar >& log_reconstructPar&

2 Post-processing the case

The post-processing is automatized, and can be executed by doing:

cd $FOAM_RUN/ercoftacCentrifugalPump/cases/transientSimpleDyMFoam/ECPMixerGgiFvMesh3D/postProcessing ./Allrun >& log_Allrun&

Likewise, if needed, the post-processing can be cleaned up by doing

cd $FOAM_RUN/ercoftacCentrifugalPump/cases/transientSimpleDyMFoam/ECPMixerGgiFvMesh3D/postProcessing ./Allclean

This deletes all the data that have been calculated from the post-processing, so be sure that you do not want to save anything from the previous calculation before cleaning up the post-processing.

3 Results

3.1 General results

Movie showing unsteady results: Media:U_3D_3.gif and Media:p_3D_2.gif

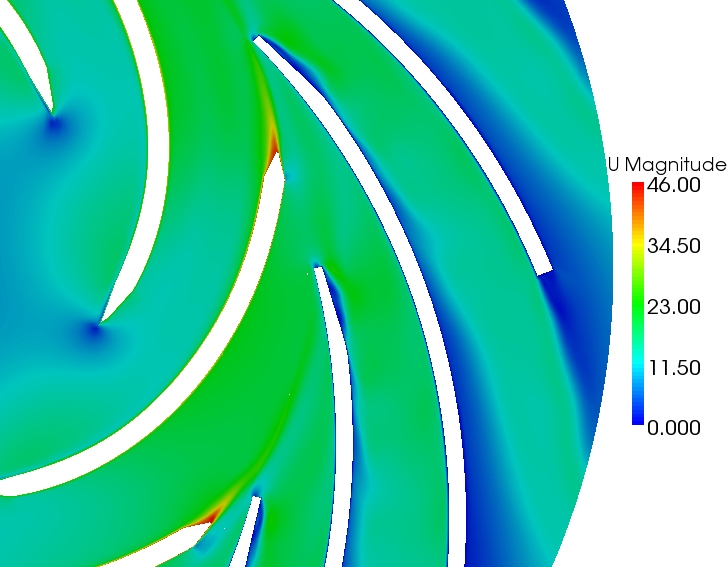

Figure 2: Velocity magnitude of the transientSimpleDyMFoam/ECPMixerGgiFvMesh3D test case at the midspan position

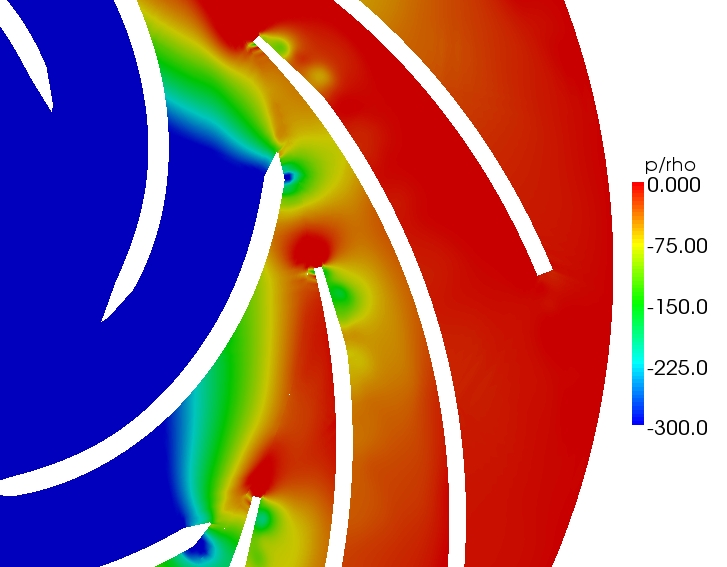

Figure 3: Static pressure of the transientSimpleDyMFoam/ECPMixerGgiFvMesh3D test case at the midspan position

3.2 Comparison with the experimental data

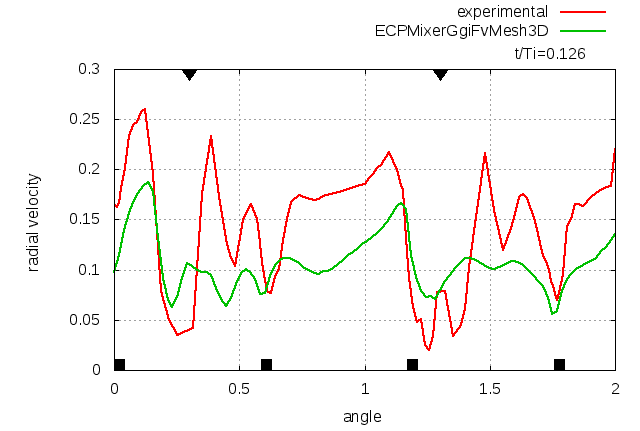

Figure 5: Comparison with the experimental data for the relative radial velocity at the midspan position (Experimental results taken from Ubaldi 1998 [2])

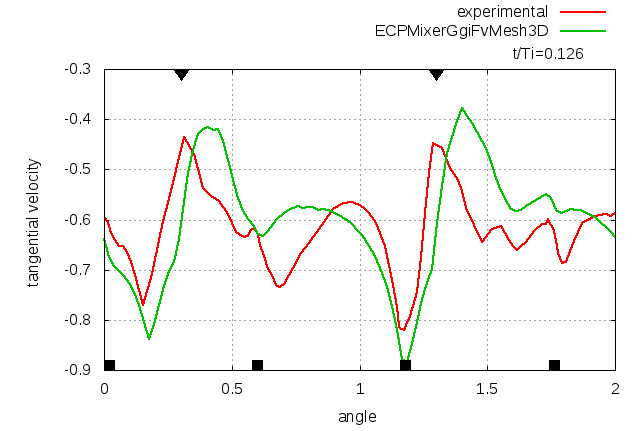

Figure 6: Comparison with the experimental data for the relative tangential velocity at the midspan position (Experimental results taken from Ubaldi 1998 [2])

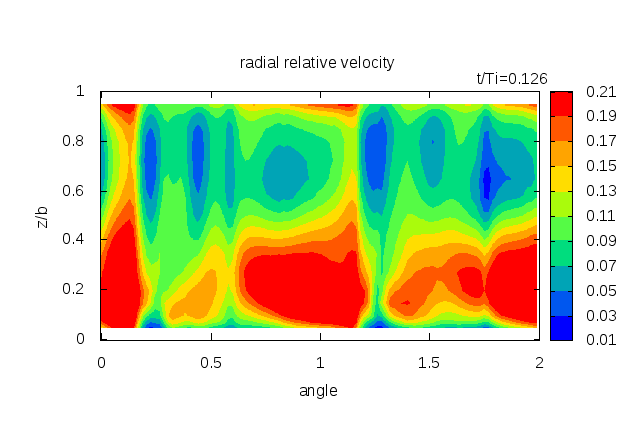

Figure 7: Comparison with the experimental data for the relative radial velocity for different span distances (Experimental results taken from Ubaldi 1998 [2])

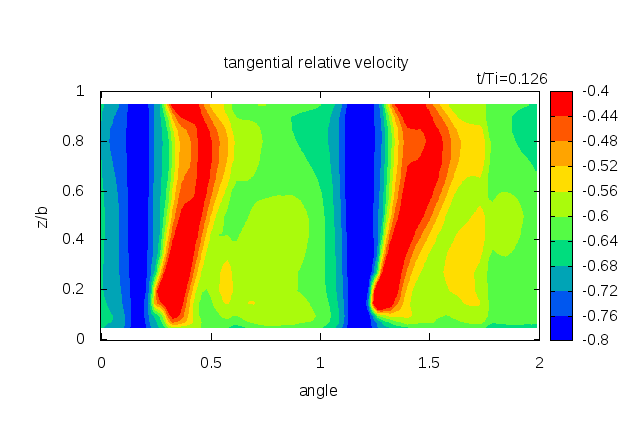

Figure 8: Comparison with the experimental data for the relative tangential velocity for different span distances (Experimental results taken from Ubaldi 1998 [2])

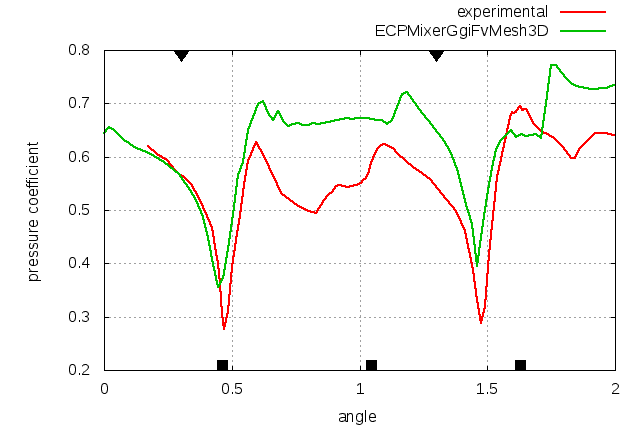

Figure 9: Comparison with the experimental data for the static pressure coefficient at the midspan position (Experimental results taken from Ubaldi 1998 [2])

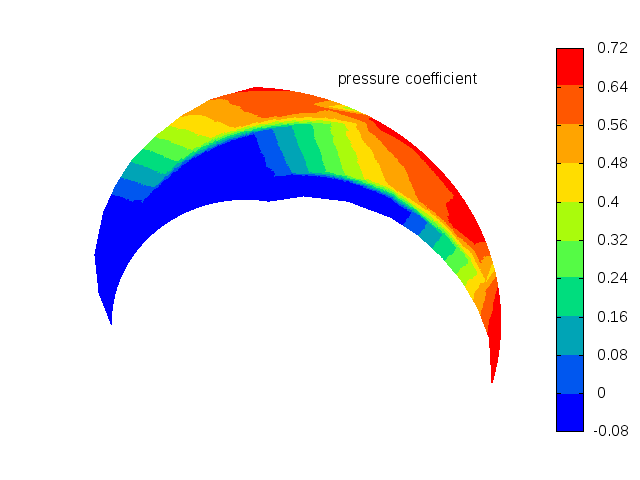

Figure 10: Comparison with the experimental data for the static pressure coefficient for different radius (Experimental results taken from Ubaldi 1998 [2])

Back to Sig Turbomachinery