The ERCOFTAC diffuser case-study, geometry and base case set-up

Maryse Page, Hydro Quebec, Montreal, Canada

The ERCOFTAC diffuser [1] is an axi-symmetric expansion of a circular pipe. Figure 1 shows a 3D view of the geometry. The inlet is in this case located at the end of the honeycomb that was used in the experiments to generate a plug flow with a solid body rotation/swirl. An artificial extension of the domain has been added at the end of the expansion. In the experiments it was open air after the end of the expansion.

Figure 1. 3D view of the ERCOFTAC diffuser base case.

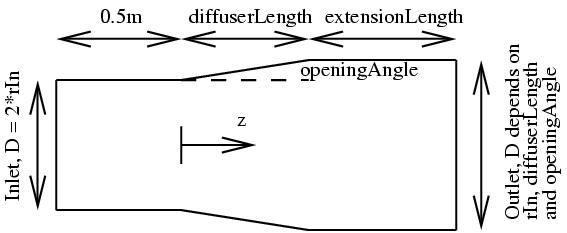

The OpenFOAM ERCOFTAC base case described below was developed as a case-study for the third OpenFOAM workshop, Milano, 2008, and it can be found at the OpenFOAM-extend SourceForge project. It includes a parametrization of the geometry and the O-grid, and a complete OpenFOAM case that solves the flow in the domain. The parametrization is made using m4, and instructions on how to run m4 are included in the case. Figure 2 shows the definitions of the parameters rIn, diffuserLength, extensionLength and openingAngle. It is thus easy to modify the geometry in terms of these parameters.

Figure 2. 2D view of the ERCOFTAC diffuser base case.

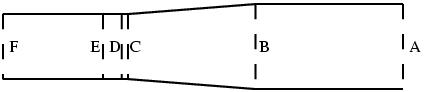

The grid generation in blockMesh is based on a number of cross-sections. It is easy to add or delete cross-sections in the m4 file if anyone would like to study another version of the same case. Figure 3 shows cross-sections A-G, that are used when making the mesh for the base case. The cross-sections refer to:

A: The outlet of the artificial extension, and the outlet of the computational domain.

B: The outlet of the diffuser.

C: The inlet of the diffuser.

D: A measurement plane.

E: The edge of a rotating part of the wall.

F: The edge of a rotating part of the wall.

G: The end of the honeycomb, and the inlet of the computational domain.

The number of cells in the z-direction between each cross-section is specified in the m4 file using parameters zABnumberOfCells (for the number of cells between cross-sections A and B), zBCnumberOfCells, etc.

Figure 3. Planes used in the parametrization.

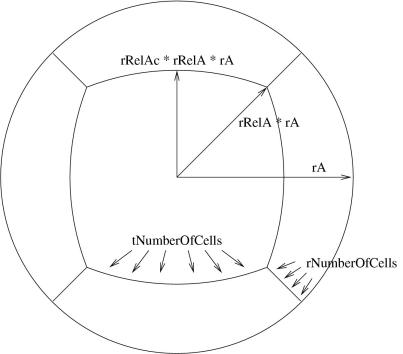

Figure 4 shows the parameters used for defining the O-grid throughout the domain. The figure is an example of the grid plane at cross-section A, but the parametrization at other planes are defined with parameters where 'A' is exchanged with the letter of the other cross-section. The number of cells in the radial direction in the O-grid is specified using parameter rNumberOfCells, and the number of cells in the tangential direction is specified using parameter tNumberOfCells (these must be integers!). The center block will thus get tNumberOfCells in both directions. These numbers are the same for all cross-sections. The grid point distribution of the center block, and thus in the tangential direction of the O-grid is uniform. The grid point distribution in the radial direction in the O-grid is defined using parameter rGrading, which is the same at all cross-sections. rGrading is the ratio between the size of the radially innermost cell in the O-grid to that of the outermost cell. That is how blockMesh generates non-uniform meshes.

The location of cross-section A in the z-direction is specified using parameter zA. The outer radius of cross-section A is specified using parameter rA. The radius of the vertices of the center block, relative to rA, is specified using the parameter rRelA, which should be between 0 and 1. In other words, the radius of the vertices may be anything from 0 (rRelA = 0, but that would make no sense) to rA (rRelA = 1). The radius of the center point of each edge of the center block is specified relative to the radius of the vertices of the center block. The edge between two vertices is thus an arc with a center radius of rRelAc * rRelA * rA. rRelAc should be between 0 and 1, where 1 gives a center block with circular edges. These definitions make it easy to modify the O-grid thickness relative to the outer radius, while keeping a high quality shape of the O-grid.

Figure 4. O-grid used in the parametrization.

References: [1] TODO: Reference to Clausen paper